SOUTH DAHRAN RO DESALINATION PLANT tr

About The Project

The Desalination Plant is located in Al Khobar (Azizyah District), near Dhahran city, Eastern Province of Saudi Arabia.

The desalination plant will be designed with the capability to match the daily and seasonal water demand profile, exhibiting high availability and reliability. The Plant will have a nominal production capacity of 50,000 m3/d, which can be increased up to 100,000 m3/d.

Our Work Scope

The scope of our work includes the following tasks:

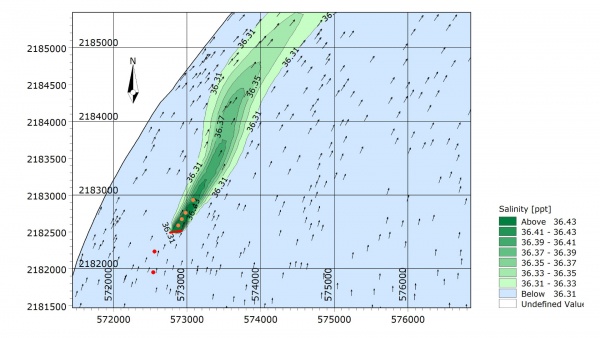

- Development of a Hydrodynamic Model (HD) of the project area to estimate the current velocities.

- Development of an Advection Dispersion Model (AD) to simulate the far-field dilution of the discharged brine and evaluate the re-circulation-related risks.

The Saline Water Conversion

Corporation (SWCC) is developing the water services for the South Dhahran Home Ownership development area (SDHO) and also for the provision of water services for parts of the Dhahran Municipality covering the SA residential area in Al Khobar (Azizyah District), near to Dhahran city, Eastern Province of Saudi Arabia.

Client: Acciona, S.A.

Contractor: Saline Water Conversion Corporation (SWCC)

Extreme Wave Modelling and Hydrodynamic Model

The general methodology employed in the studies can be summarized as follows:

- The first HD model of the Arabian Sea was developed, then calibrated with available water level measurements from the project site,

- The calibrated model was used to simulate current fields in the project area and coupled with the AD model, which was set up for the same area,

- The AD model used initial mixing results from the diffuser design as source input and far-field transport of the plume was simulated. The salinity behavior and thermal plumes were investigated.

This cascaded approach provided both speed and control for the engineers.

All the modeling work has been carried out by ARTI Proje, utilizing the state-of-the-art numerical modeling software MIKE21 of DHI.